* please PM if there is anything that should be added or corrected*

Here is a simple guide to those people out there wondering where to start with modifying their EJ20/25T’ engines. I will cover the 3 main sources for a complete combustion to take process. The principle of “do it once, do it right” will come into play.

NOTE: Im not saying that this is the cheapest or easiest method at all. Just that it works and you wont have to redo or change it due to poor quality

FUEL

Fuel pumps, The first thing to do when deciding to upgrade your fuel system. These bad boys are the backbone in the fuel system. Without them we wouldn’t be able to get fuel from the tank to out beloved engine. One that is capable of pumping more fuel per minute is optimal for later stages of fuel delivery. Walbro and Bosch are the Major brands doing the rounds in modified Subaru tanks.

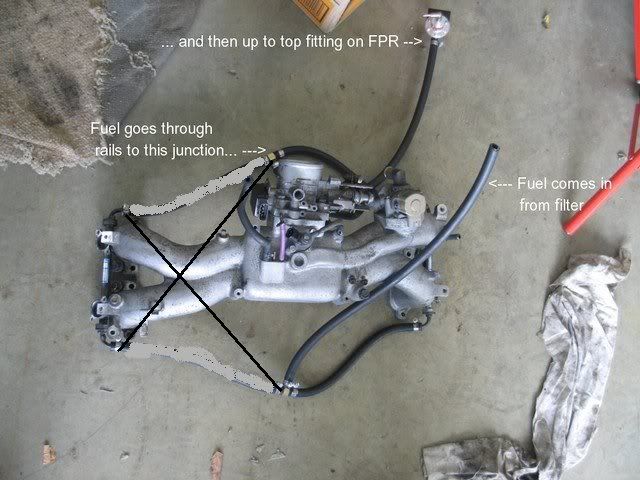

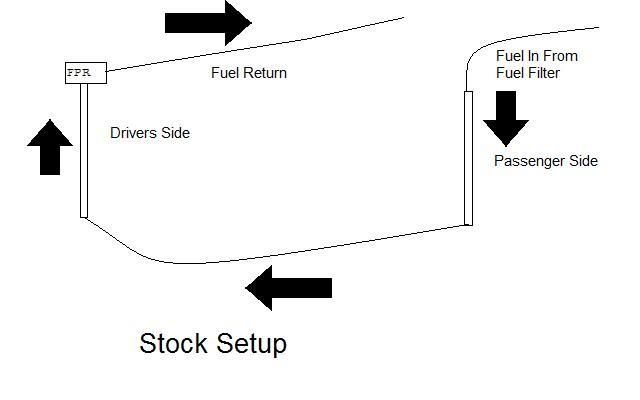

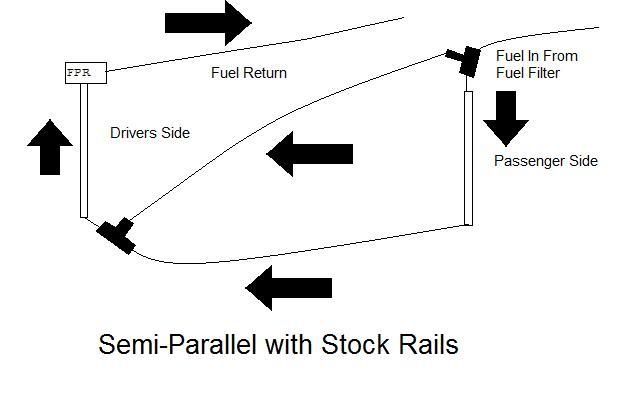

As some of you may or may not know in Subaru engines (particularly early model Ej20’s) cylinder #2 is prone to run leaner under high boost and RPM applications than the other cylinders in the engine. This is due to the design limitation of the Stock fuel system. This results in cylinder #2 being starved of fuel.

A semi parallel fuel rail mod can fix this very easily by running additional fuel lines in between each bank.

A full Parallel mod can be done which has been done on many members cars. its a pretty easy DIY, but mick at Techworz in ACT can do this modification for the $300ish mark. (not including FPR. Using Two left hand rails with no fuel pressure regulator. this setup can easily be achieved. (see below posts for MARV's comments)

Next on the list are fuel pressure regulators. These little buggers can increase fuel pressure as boost rises. The pressure set can determine how the fuel is sprayed out of the injectors. “Too Low” pressure will cause the spray pattern to form a dribble and the fuel will be located and ignited on one part of the piston. “Too High” pressure will allow a big wide mist to come out which will be directed towards the outside of the combustion chamber and cause a possible misfire due to the sparkplug not being able to reach the fuel. The optimum pressure should produce a fine mist that covers the whole combustion chamber allowing for a complete burn. Some brands that are used today are SARD, HKS, Etc..

Injectors, now the rule goes that you want 25 percent more flow than what you need. Early Ej20T came with 380cc injectors which are great for the 160KW mark. MY97-98 STis and GT-B Legacys had the correct 440cc yellow top injectors, but MY99-00 had a different side-fed injector. You can make the 99-00 injector work in an EJ20G (MY89-96 EJ20), but you need EJ25D fuel rails off a gen2 NA 2.5L Liberty/Legacy.

From MY01-on they used top-feed injectors (380cc, 440cc, 550cc) which has a wider range in aftermarket injectors.

A basic guide is:

160Kw’s 380cc

180Kw’s 440cc

200Kw’s 550cc

230Kw and up 650cc

SPARK

Now once all these components have been upgraded its now time to look at Spark

A common fault is the aged Coils breaking down and failing when the boost is raised. An upgrade to Bosch HEC716 coils is a great option. Up rated ignition leads are a must when the coils are changed. Resistance in the ignition leads can lead to poor spark and engine misfire. Spark plugs are next and gapping them is they key to a good ignition. If the gap is too small the spark won’t have enough to completely burn the fuel in the chamber. If its too big the spark may get blown out by the compressed air being forced into the engine from the turbo charger. A gap of 0.7mm is recommended for the EJ20T and slightly smaller if boost is substantially higher than factory.

By changing these components you will now know that your ignition system is great and will not fail you any time soon.

"courtesy of TZlegacy"

AIR

This is the unit that give us the power, the rule is more air = more fuel = power.

The stock Subaru intake tract is very restrictive due to a resonator located in the inner guard adjacent to the airbox. The simplest method is completely removing the resonator and airbox from the intake and attaching a Pod filter to the end of the Air Flow Meter. This does however give the engine a mighty roar as you stomp on the loud pedal but increases the risk of sucking in hot under bonnet air. A custom Cold air induction is great. This compromises of stainless or mild steel pipe work which goes from the turbocharger, through the hole in the side of the engine bay and ending inside the inner guard where cold air can be sucked in. You can buy kits which re locate the AFM inside the guard which also aids in positioning and cost effectiveness of buying expensive stainless steel. Such Companies as Techworkz and Amauto can make custom kits to suit any application.

The infamous duel 90 degree bends just before the Turbo are restrictive. due to the sudden change move direction the air has to travel. this causes turbulence and the air does not get sucks in as efficient as it could. As Marv has stated a Gen2 Airbox can be installed to still have the Stock style box and it can also work with those who have FMIC piping to suit the inverted core.

“Techworkz Cai”

EXHAUST

The exhaust system, Its job is to extract the exhaust gas’s and exit them out the rear of the vehicle as quick as possible. Too restrictive and the engine will choke in higher RPM/Boost. Too free and the engine wont have the back pressure to allow the gas’s to be sucked out.

Please refer here for a more indepth view > http://www.subyclub....hp?showtopic=54

A 3” system from the back of the turbocharger is the best option, Don’t stuff around with Catback or diffback systems as it will cost you more in the long run if you decide later that you want to complete the system resulting in a full 3” system. A free flowing muffler is must as the standard item is very restrictive due to multiple baffles as it tries to meet noise regulations. Any local exhaust place will be able to make up a system for your needs.

some workshops insist on a 2.5" from the diffback to add to a 3" system. this is to aid i midrange performance and form a "venturi" effect much like a carburettor. This happens because as the pipe diameter gets smaller the air speed is increased. which is great for an exhaust system.

This guide to basic performance is simple and has been tried by many fellow Subaru owners and proven that it works.