Posted 08 April 2018 - 06:37 PM

Follow me on Insta: @brzdiy

Posted 10 April 2018 - 11:49 PM

Posted 11 April 2018 - 08:12 AM

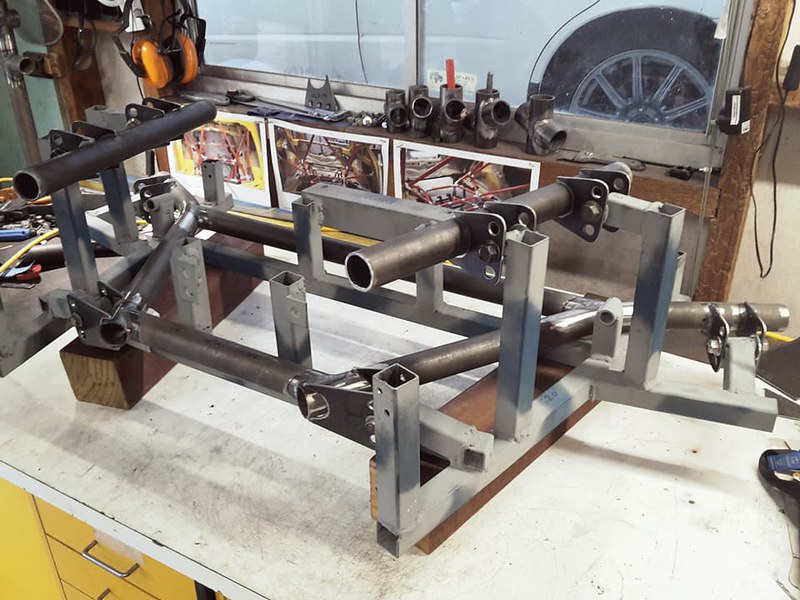

Neat work Joel!

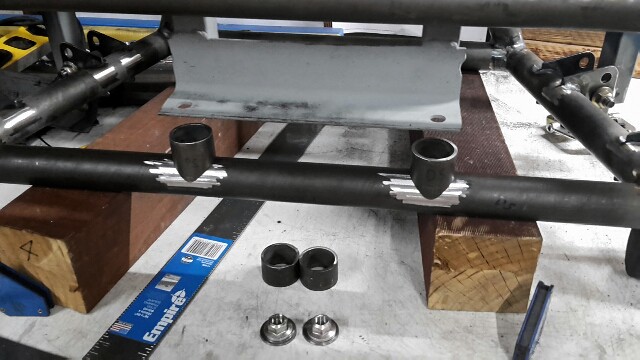

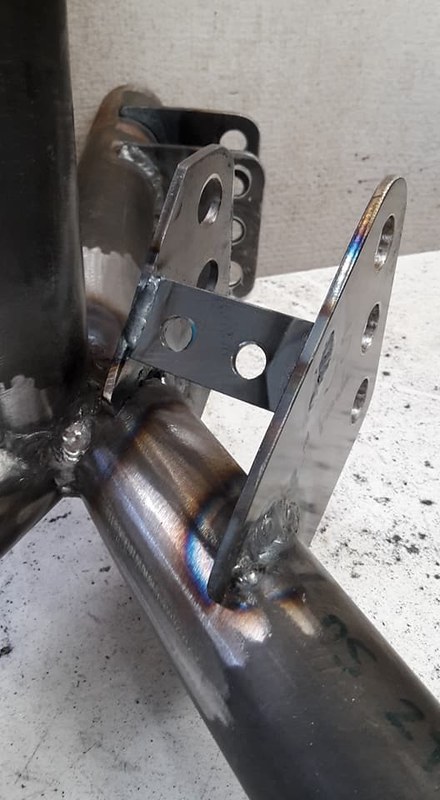

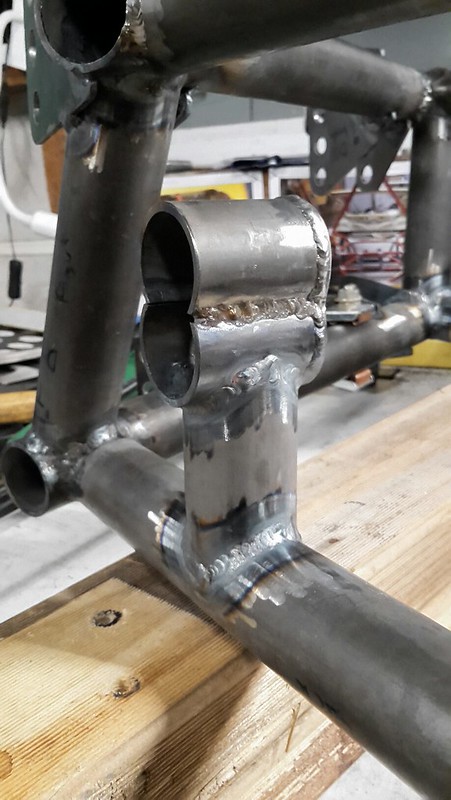

How did you cut the plates from the steel? Very clean cuts!

And how are those upper tubes held in place at the moment? There doesn't seem to be anything supporting them other than the bolts holding the suspension mount plates in place. That, to me, opens up loads of room for misalignment or error.

That said, I've not done anything like this before, I'm only observing your quality work. So please don't take offence, I'm only meaning to be open about what/how I see your work. You've probably got a plan in place for this anyway I'm sure.

Keep up the good work!

Cheers

Bennie

Hi Bennie,

I'm just using an angle grinder with thin cut off wheels to do the cuts, a bandsaw would be better but I don't have one.

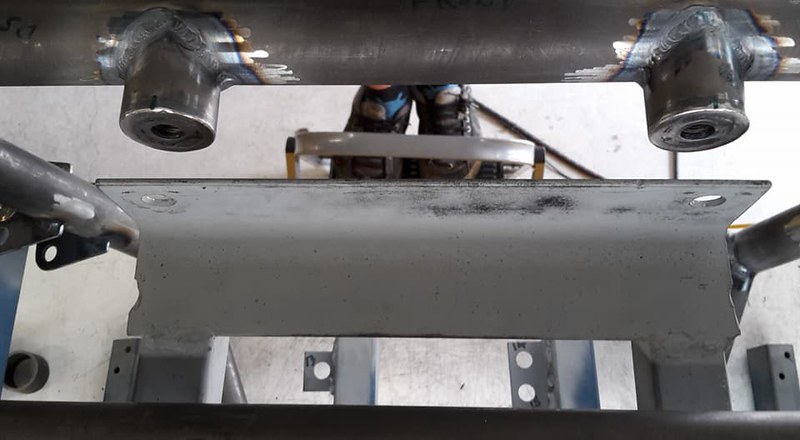

The upper tubes are held there because the circles cut into the tabs are slightly larger than the radius of the tube. They are only there now as a mock up so I can visualise the next steps.

Cheers

Joel.

Follow me on Insta: @brzdiy

Posted 11 April 2018 - 02:05 PM

Posted 11 April 2018 - 06:53 PM

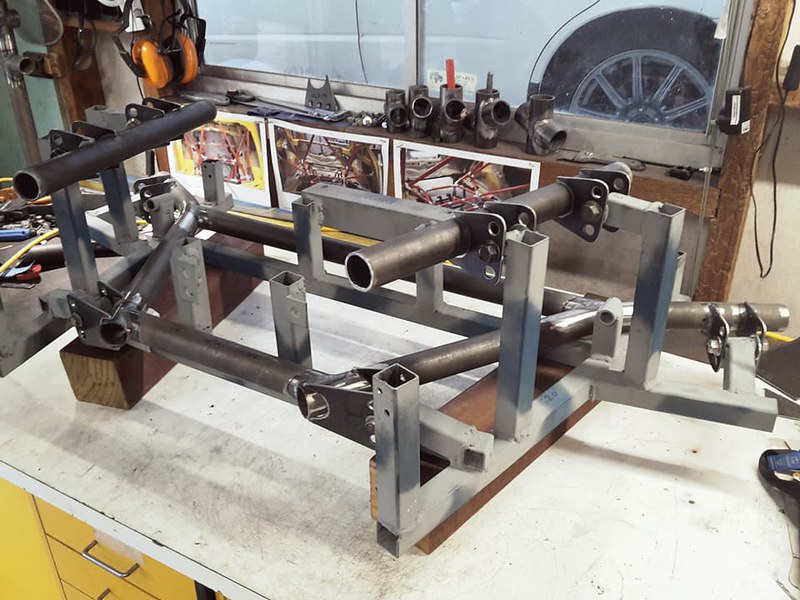

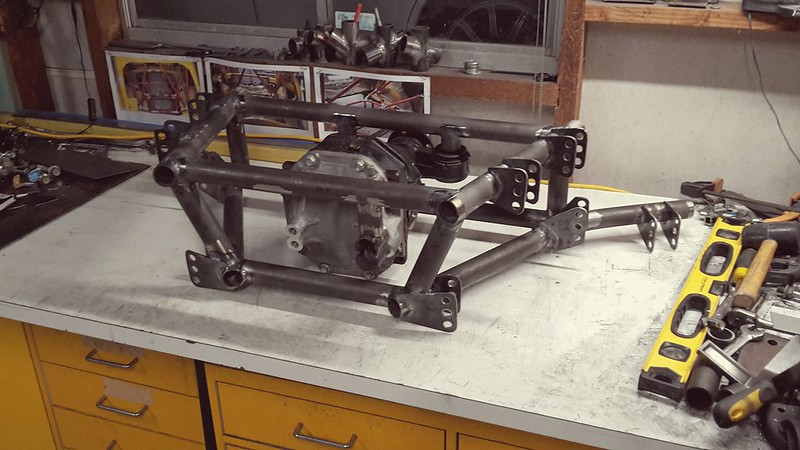

Holy hell, this is all taking shape.

Saw your post on 86 Track Cars as well, you will blow some of those Yank's minds when this is complete.

As always, can't wait to see it on the track. Will it be ready by Subinats?

Sent from my CPH1607 using Tapatalk

Thanks mate, I appreciate it.

No it won't be ready for Subinats and unfortunately it won't be eligible once complete as I have decided to run a Honda K24 engine it it.

Follow me on Insta: @brzdiy

Posted 11 April 2018 - 06:57 PM

Follow me on Insta: @brzdiy

Posted 15 April 2018 - 08:45 PM

Follow me on Insta: @brzdiy

Posted 15 April 2018 - 09:07 PM

Posted 16 April 2018 - 07:40 PM

As always mate, effort and workmanship look tops!

After all this can you build me a front bar for my L series??

Cheers

Bennie

Thanks Bennie,

Follow me on Insta: @brzdiy

Posted 17 April 2018 - 07:36 PM

Follow me on Insta: @brzdiy

Posted 17 April 2018 - 11:14 PM

Posted 18 April 2018 - 05:43 PM

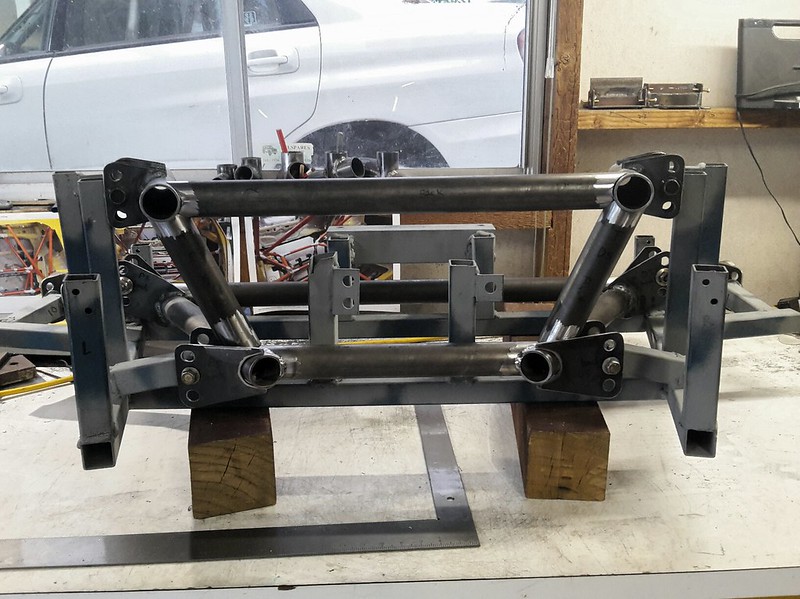

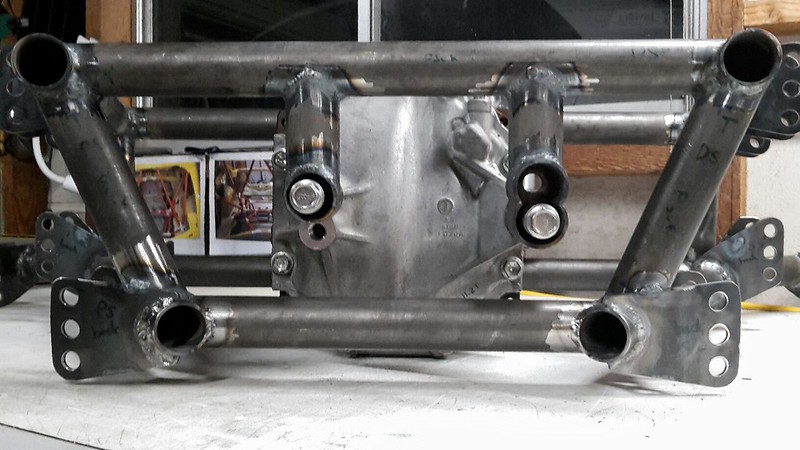

I bet you can't wait to remove that jig. It's really looking like something now!

Cheers

Bennie

Yeah that will be good, this subframe has been a real fun project, very enjoyable.

Follow me on Insta: @brzdiy

Posted 25 April 2018 - 06:48 PM

Follow me on Insta: @brzdiy

Posted 28 April 2018 - 08:15 PM

Follow me on Insta: @brzdiy

Posted 29 April 2018 - 11:58 PM

Posted 30 April 2018 - 07:01 PM

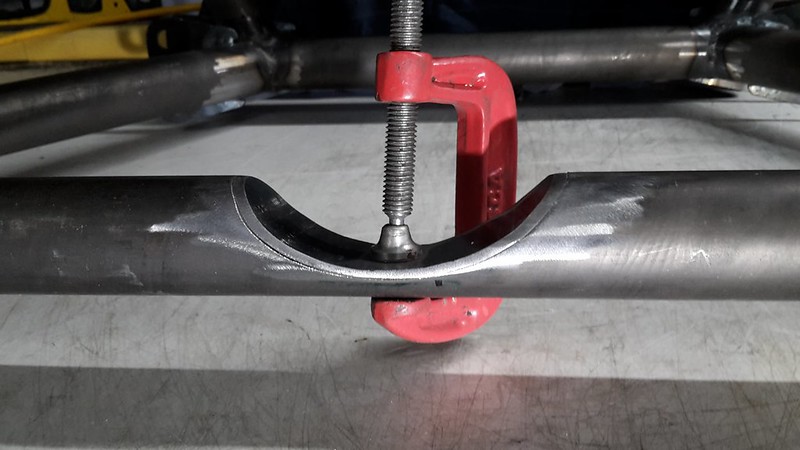

Would you consider bending and remaking that whole lower pipe instead of the cut and shut you've proposed?

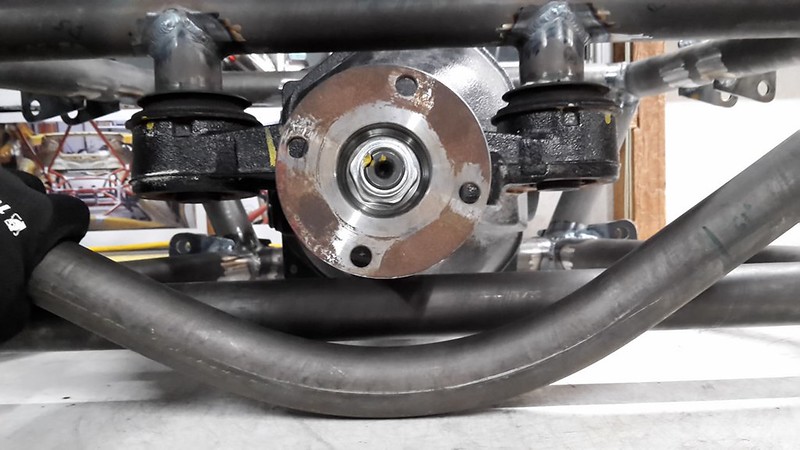

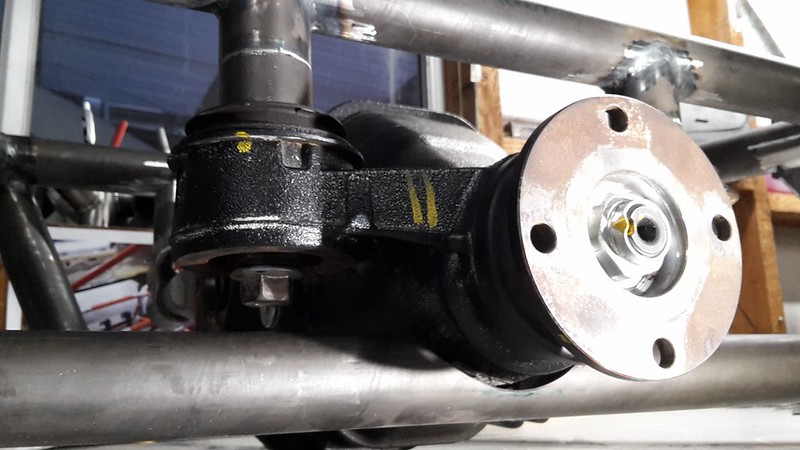

The frame outside of the jig looks awesome - and I bet you were very excited while mounting the diff in it!

Cheers

Bennie

Hey mate, that is not really an option as the vertical tubes also join to this horizontal tube. I ran some ideas by my mate that did the original FEA on the design today and we have a pretty neat solution. You will see some updates soon.

Taking the jig off was a great feeling, another milestone in the build!

Joel.

Follow me on Insta: @brzdiy

Posted 02 May 2018 - 07:26 PM

[/url]

[/url]

Follow me on Insta: @brzdiy

Posted 02 May 2018 - 08:19 PM

Posted 02 May 2018 - 10:30 PM

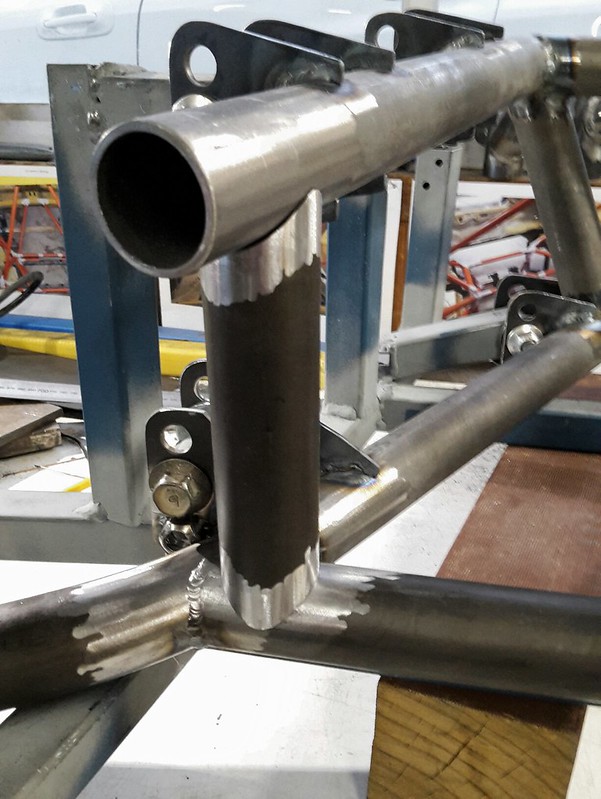

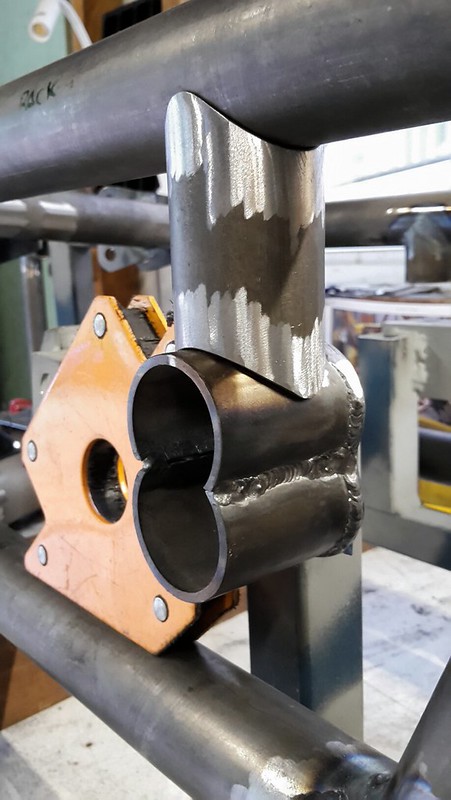

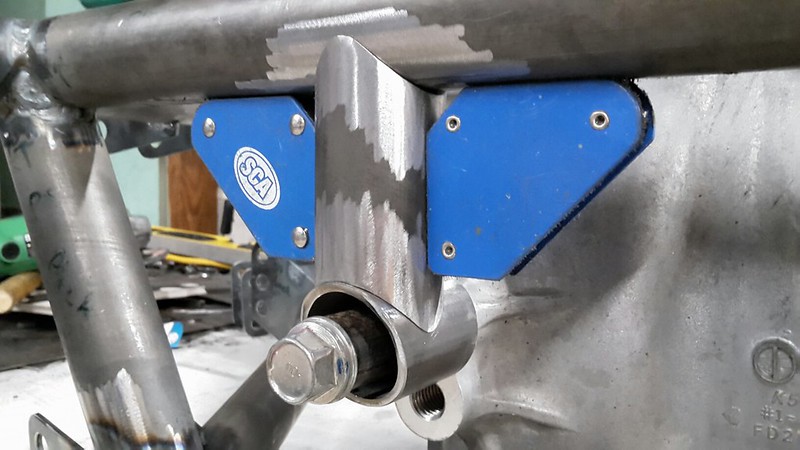

"took a while to get the curve to match the notch" - more like be a part of the frame! That's a top effort for fitment!

I didn't see that as part of the solution and realise that you're not done yet either. I'm imagining a small vertical bar across the bottom to help strengthen the bar further is the rest of the solution...

Will you weigh up the frame once it's all done to compare it to the stock frame weight?

Cheers

Bennie

Sometimes I get a little OCD and won't settle for anything less than a perfect fit ![]()

I am still hoping to use one of my scrap bends to reinforce the tube but its going to take a fair amount of cutting and grinding to get the fitment I want. Being bent will also make it more awkward to handle whilst doing all that.

Yes I will do a weight comparison, the FEA has already given me a weight for the entire structure including rear stays connecting to the main hoop of the roll cage and this was less weight than the stock frame, but it did not account for all the tabs the control arms connect to.

Joel.

Follow me on Insta: @brzdiy

Posted 06 May 2018 - 08:32 PM

Follow me on Insta: @brzdiy

0 members, 0 guests, 0 anonymous users