Upgrade Hybrid Turbos

#41

Posted 07 February 2011 - 09:32 PM

#42

Posted 08 February 2011 - 02:47 PM

Its pointless being skeptical with no evidence eitherway. As a rule I'm skeptical of everything out of the ordinary. That said, I've only every seen (really) shit curves from B4's. So I don't know.

Just for you Soop, another B4 with mild mods - See link from ozlib -> My link

#43

Posted 08 February 2011 - 06:45 PM

This has sort of confirmed for me what I was going to try anyway to combat the vod. Which is to initiate the pre-spool sooner and delay the I/C valve opening till a higher rpm.

Only info I could find on the Porsche was that pre-spool and changeover occurred higher in the rev range - after 4000rpm. But nothing on how the system operates.

#44

Posted 08 February 2011 - 06:59 PM

Try teamspeed.com for some tech. on the P-car system.

Cheers,

Nik

#45

Posted 09 February 2011 - 09:58 PM

with it done correctly, the right turbos for the setup and the right tune i see no reason why a TT cant be very successful even on a 2L.

unfortunately my TT experiments are over as i bought a house and am selling the car.

But i had collected 90% of the parts for a rather complicated compound/sequential setup using 2 garrett's aiming at 300atw.

the limit i reached was either the under manifold pipe or the turbos flow capacity, im not sure which as i didnt get round to changing the pipe to find out.

the 2L made more peak power at higher RPM, but the 2.2 had a broader delivery and went like stink with no vod at all.

after about a month i ran it parallel with 2 secondarys, which made it a lightswitch at dead on 4200rpm, but boost kept tapering off top end making me think it was the intake pipe that couldnt supply the turbos.

the keys to the success i sure is to ditch the subaru designed ECV and control the flow with a free flowing valve such as a large ceramic ball valve or high temp stainless butterfly after the turbo.

i found these available, but at very high cost for something that i wouldnt worry about failing.

and the IC valve (if your design has one) needs to be operated by the pressure from the staging turbo, not a setpoint controlled by an ECU which in the stock setup always opens too early (its part of how ecutek gets it so smooth by retiming it)

and obviously to have the right turbos for the application. the better the system works the bigger the turbos can be.

if anyone in adel wants to be a guinnea pig, let me know. i still want to build this monster

......................................

#46

Posted 10 February 2011 - 01:45 AM

But on topic, this thread is awesome, very keen to see where it gets to. I too thought about this, and asked a few questions on ozlib with the basis of a 2.5, but after talking to regency, the idea was canned due to them not willing to let me register it after I was finished. Best of luck with it!

Billsy - how much help were you after? Send me a PM with what bits you have and what you would need to make it happen. I have to say, I am somewhat curious. Only point is, it will have to be done on the sly. If the missus finds out this is in the works, I'm a dead man

Cheers,

Ben

MY00 Red RX, a nice daily that was sold off once the B4 became reliable...

MY02 Blue B4, aka 'The Project' - v8 JDM STi engine package and assorted other 'goodies' - Sold, then bought back for parts. Stripped and crushed.

MY03 Blue RX, the newer old daily, pretty well more B4 than RX now... In the process of being converted to the track toy... Watch this space!

MY02 Silver Wagon, H6 conversion, full blue/black leather and almost full black interior to go with it. In process of being stripped and sold off.

MY03 White/Silver H6 Outback, donor car for silver waghoon. Scrapped.

MY97 Silver RX, acquired to become track car, but plans changed. Scrapped.

MY13 BRG, current daily, very nice to drive, small mods to make it even nicer again.

#47

Posted 10 February 2011 - 09:34 AM

Billsy did you ever modify your I/C valve to operate off positive pressure? I'm curious as to the effectiveness of this as I have thought about it but the problem I saw with it was getting it to operate smoothly. Too soft a springrate and it would open too early, cause reversion, close again and repeat the process. Too hard a spring rate and the valve would never open until the secondary is boosting higher than the primary, this would cause massive surge I would think. The bypass valve would also have to be modified to operate as a regular BOV taking its signal from the manifold so low rpm pre-spool would be compromised. If you have made this work I would love to hear how you did it?

Compound would be cool. But won't intake temps reach massive, probably dangerous levels? Will you lower compression ratios to combat this? Or just manage it with good cooling and a conservative tune? I'd be very interested to see the results of such a system.

Nik, teamspeed.com was a good place for a perve but unfortunately they had very little info on the elusive 959.

#48

Posted 10 February 2011 - 11:30 AM

Liberty B4 2002 BE5 Rev E 2.5L BITURBO TF035HL-14GXT E85

#49

Posted 10 February 2011 - 11:04 PM

its downright terrible, both in design and as far as fluid dynamics goes, it creates massive turbulence even when ported it leaves much to be desiredThe stock ecv seems to be quite restrictive without porting it out.

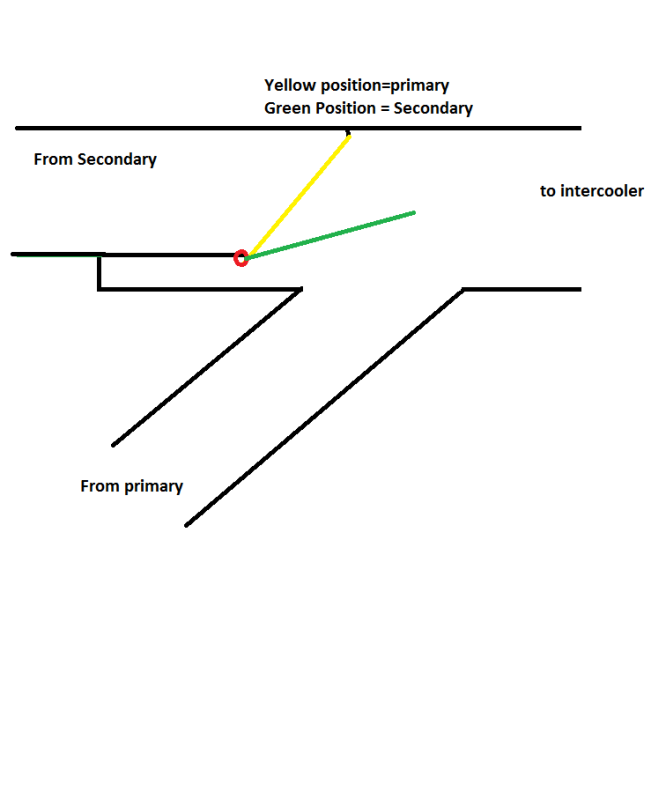

it was basically as in this pic, and it explains itself, the pressure from the primary keps it closed, when the secondary has something to contribute it just opens and self adjusts to the flow of each turbo.Billsy did you ever modify your I/C valve to operate off positive pressure? I'm curious as to the effectiveness of this as I have thought about it but the problem I saw with it was getting it to operate smoothly. Too soft a springrate and it would open too early, cause reversion, close again and repeat the process. Too hard a spring rate and the valve would never open until the secondary is boosting higher than the primary, this would cause massive surge I would think. The bypass valve would also have to be modified to operate as a regular BOV taking its signal from the manifold so low rpm pre-spool would be compromised. If you have made this work I would love to hear how you did it?

it worked VERY well, and allowed me to controll changeover with just one signal wire from the ecu or switch on the dash. (with vac line modifications aswell) it eliminates the valve timing fuckups that subaru tuned into the ecus

i made it from 40 and 50mm stainless tube, stainless hinge and valve flap.

the compound would only be during primary operation and once the much larger turbo kicks in the primary is bypassed, using similar passive valving as above it automatically goes back to the smaller turbo once the smaller one out flows the larger etc. its a modified version of what mercedes now use on their twin turbos, ive had it planned for about 5 years and it never really got off the groundCompound would be cool. But won't intake temps reach massive, probably dangerous levels? Will you lower compression ratios to combat this? Or just manage it with good cooling and a conservative tune? I'd be very interested to see the results of such a system.

......................................

#50

Posted 11 February 2011 - 10:04 AM

Your compound system also sounds similar to Volkswagon's system on the golf super + turbocharged setup. Just thinking about it, and what a fiddly and frustrating job that will be trying to fit the pipework in!

#51

Posted 11 February 2011 - 11:40 AM

if it was upside down then gravity would eliminate your concern anyway.

also it has low pressure from the turbos intake (through the secondary)on the other side aswell to keep it shut. although the effect would be minimal.

along with the front mount it was the single best mod for smoothing out the TT transition

......................................

#52

Posted 11 February 2011 - 04:02 PM

Ta

Aaron

#53

Posted 14 February 2011 - 04:32 PM

#54

Posted 14 February 2011 - 05:11 PM

#55

Posted 14 February 2011 - 05:25 PM

I would take dynographs of other people's cars with a grain of salt.

The only graphs you should be looking at is your own, going back to the same, consistent dyno.

Only then, you can compare your own graphs with yourself, and then gauge true gains.

Comparing one person's graphs from SA, to another person's in QLD is like pissing in the wind. It's messy, and achieves nothing.

There are no constants to compare against.

I'm sceptical of that curve

ken oath x1billionz. dyno is JUST A TUNING TOOL. it can be manipulated to show anything! a 100kw car can make 200kw on the dyno with hardly any work from the operator!

dyno smoothing is a very common practice. makes the customer happy

i admit it is a good power curve however ALL SEQUENTIAL TT's WILL HAVE CHANGEOVER. map a boost curve below that and will tell the story.

props to all the effort you are going to. DIY mods are epics wins big learning in them and sometimes a very little costs for some handy gains. great work!

MY07 GT spec B

#56

Posted 14 February 2011 - 06:14 PM

Ecutek Stage 2, 3" DBE, Walbro FP, Hyperflow CAI

14.2 @ 158kph

#57

Posted 14 February 2011 - 06:27 PM

There is a before and after pic of a ported ECV on this page:I dont really understand how the Electronic control valve can be ported? Can someone explain this to me? Is the little gate just trimmed to make it lighter and easier to open?

http://www.subyclub....b4/page__st__40

Liberty B4 2002 BE5 Rev E 2.5L BITURBO TF035HL-14GXT E85

#58

Posted 15 February 2011 - 06:26 AM

Just thought I would share what I have been up to over the past couple of weeks.

Rather than travelling down the tried and trusted path of binning the twins and strapping on a massive single I thought I might try and see just how far I can take the twin setup. This is just the first step and involves the 2 new turbos and intake pipe. Next step will be fitting a dual core vertical FMIC, bigger IC valve and I have an idea for a set of headers that I would like to try.

This is the 2 OEM turbos on top and the new hybrids below - secondary's on the left, primaries on the right. OEM is VF18/19 and the hybrids are TD04-13T/VF25 primary and TD04-13T/VF14 secondary. I have kept the wastegate on the secondary for future use. (might be necessary after the headers are done)

VF18 on the left, hybrid on the right. This clearly shows the difference in compressor size between the two.

Again, VF18 on the left, hybrid on the right. You can see the turbine wheel is much larger so flow should improve and it will be capable of driving the larger 13T comp wheel. The turbine wheel has been replaced with a TD04 wheel rather than the TD04L wheel which is used from factory. The 2 wheels share almost identical exducer's and inducer's however the standard TD04 wheel has a slightly shorter tip height. This reduces weight of the wheel and flow capabilites which should help reduce lag on spool up, particularly at changeover.

This is the 2 primaries again. Bit hard to tell but you can see that VF25 turbine housing on the hybrid is much smaller than the VF18. This reduced AR ratio should help with spool up as the TD04 core is journal bearing as opposed to the VF18's ball bearing core, also the physically larger wheels will now be much harder to drive too.

New intake pipe. I have made it from 2.5 inch mild steel and 63mm radiator hose and coated with a layer of high temp engine enamel. This is a total pain in the arse to fit as there is only just enough room for the standard plastic pipe as it is. I have had to delete plumback section for the BOV just before the primary, and also the crankcase breather that plumbs back into the OEM pipe just under the TB. This will insted be rerouted to a tee piece between the secondary bypass valve and intake pipe. PCV valve will also be deleted as I can't be bothered rerouting those hoses too (there just isn't enough room to work with). The 3 smaller pieces up top are 2 inch mild steel and are used from the compressor outlets -> TMIC.

The maths I have done suggest that airflow from these 2 puppies should be ample for a good power figure but I am in no way going to make any predictions yet. Just going to see if it actually works first - the turbos might respond poorly and it will just be a real pig to drive

P.S. apologies about the quality of pics, apparently the card in the camera was corrupted so I have just used my phone.

Ta

Aaron

good luck! but this hybrid turbos is come from what car?

#59

Posted 15 February 2011 - 08:54 AM

TTimpreza, Turbos are a TD04L from the wrx. They are hybridised from switching out the turbine housings with those from the standard IHI VF turbos fitted to the TT engines. The housings have to be machined out to accept the larger turbine wheel from the TD04 turbo. Housings from any series of the TT engine can be used with the difference being varying A/R ratios.

#60

Posted 15 February 2011 - 02:40 PM

Primary turbo. Not the neatest setup but it will do for now. The compressor housing is rotated outwards in preperation for the FMIC. Combination of 50mm mild steel and radiator hose to loop it back towards the TMIC. This is why I have deleted the plumb back section for the BOV.

Secondary turbo. This was time consuming as the ECV actuator bracket collided with the larger compressor housing so that needed a section carved out of it. Then the wastegate actuator collided with everything so after trying 2 different sized actuators I just removed it and wired the wastegate shut. I don't need it yet anyway, it's just there to future proof further mods.

Above pics is the first actuator I tried, then a smaller actuator, then wired shut. The circled bit is where I hard to take a chunk out of the ecv bracket.

I should be able to get stuck into it again tonight so if all goes well I should be able to have it up and running within the next couple of nights.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users