Happy new year to you all.

Not a lot has been happening with the car with Christmas and all that but yesterday I did manage a full day of work on the front suspension.

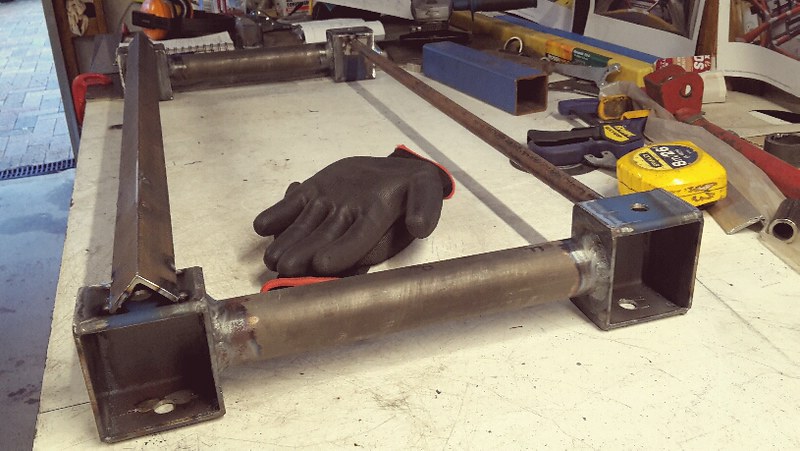

After lots of back and forth on the design I finally came up with a method to attach the inner control arms to the chassis. Similar to the rear I wanted to be able to adjust the geometry as much as possible.

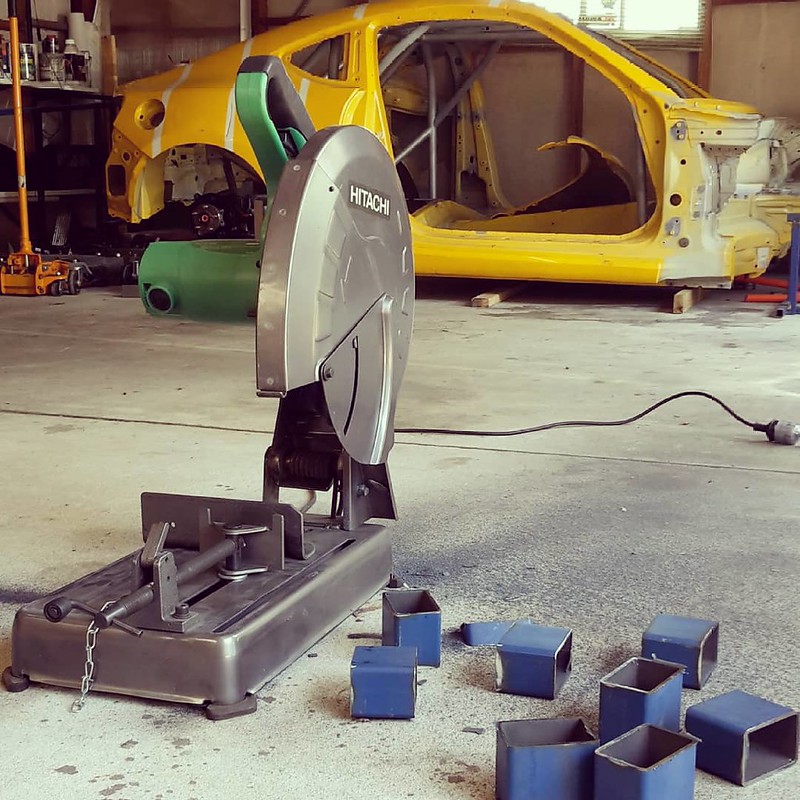

I started out with cutting up some 75mm x 50mm x 3mm rectangular box steel.

Then I cut out one face of the box. There are 8 in total which is enough to do upper and lower control arm mounts on both sides of the car.

Then I had to cut out 16 squares from 3mm sheet to box in the open faces.

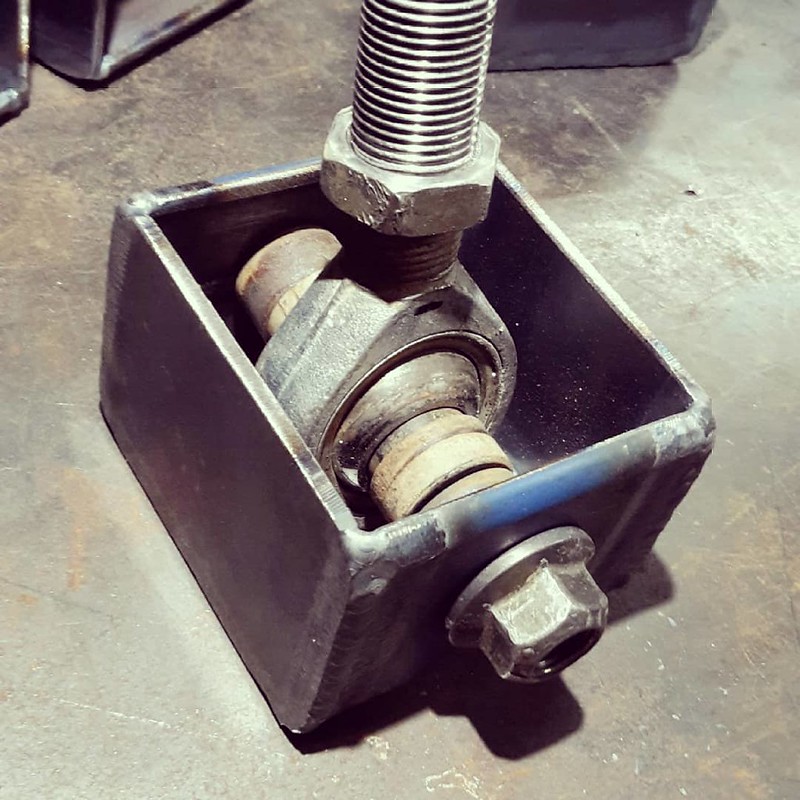

I then tig welded them all and it took a really long time! I calculated after I had finished that I had welded 2.8m in length. Anyway it was really good practice and by the time I welded a couple my settings were dialed in perfectly and my welds were very consistent.

I also beveled both faces before welding for maximum penetration.

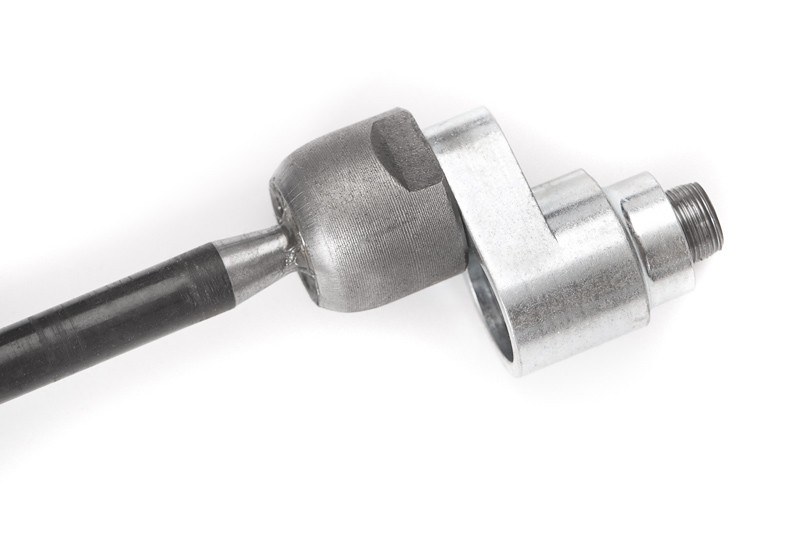

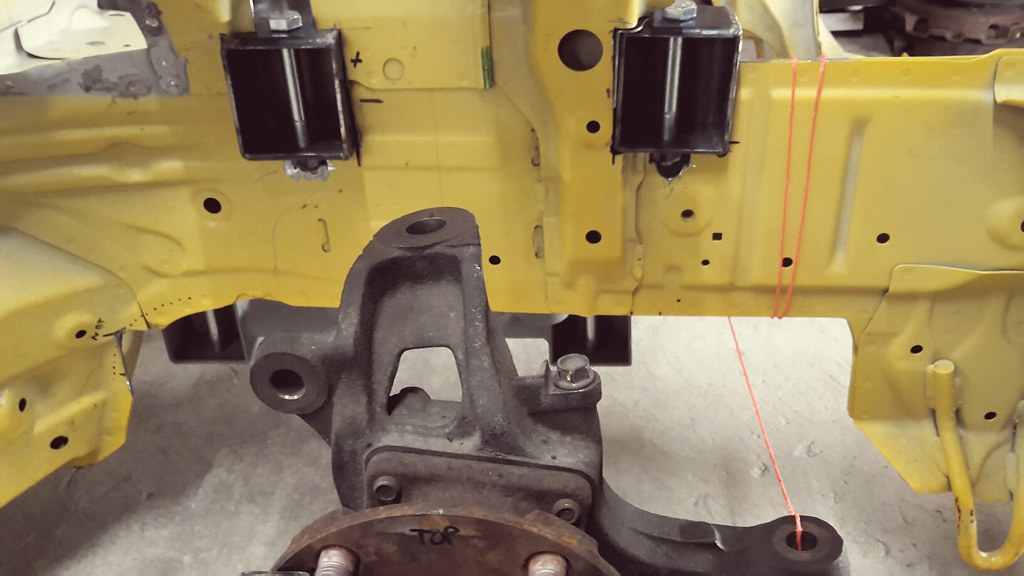

So this is the finished product before it gets welded into the chassis. The rod end is just an old one I had from my wrx to show how it works. I will be using one size smaller than this when I do my bulk order for all the control arms.

They will be mounted in the chassis with the bolt running vertical so the rod end is sitting horizontal. This will allow me to use spacers to position the rod end on the bolt at different heights to adjust the pivot height which changes control arm angles for camber gain and roll center.

Using the rod ends also allows me to adjust the length of the arms for static camber and caster adjustment.