Posted 18 February 2018 - 07:13 PM

Follow me on Insta: @brzdiy

Posted 18 February 2018 - 08:36 PM

Posted 20 February 2018 - 08:30 PM

Awesome, loving the detail going into this.

Posted 25 February 2018 - 02:32 PM

Cheers guys, love the feedback.

Follow me on Insta: @brzdiy

Posted 07 March 2018 - 05:53 PM

Follow me on Insta: @brzdiy

Posted 07 March 2018 - 06:23 PM

Awesome bit of pipe work going on there!

Cheers

Bennie

Posted 11 March 2018 - 06:46 PM

Follow me on Insta: @brzdiy

Posted 13 March 2018 - 07:31 AM

Posted 13 March 2018 - 07:57 PM

As a fabrication engineering student, Im blown away by your endeavour. Amazing and as usual, inspirational.

I just reread the whole shebang on ft86 and the extra pics really joined the dots for me.

May I ask what is the split between MIG and TIG welds on the cage and subframe, and how do you decide which process suits each part or location?

Thanks mate,

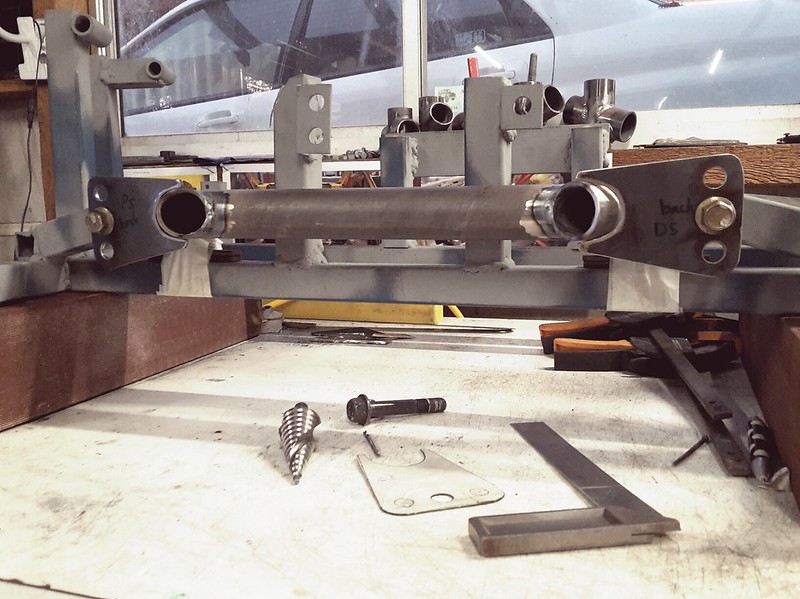

The short answer is TIG wherever possible, MIG for everything else.

Long answer. For the roll cage I went with TIG as I am much more precise with this process and I know I am getting full penetration and fusion in all the joins and it looks much neater. An experienced welder can also achieve that with MIG too but I don't have enough experience with MIG to weld the joins in the cage with any real confidence.

The areas I have to use MIG are where I am joining the rocker boxes and rear mounting plates to the chassis. This is 3mm thick steel joined to 1.5mm sheet metal which is more difficult than welding metals of the same thickness. The main reason for MIG here is that TIG requires 100% clean metal and it is very difficult (almost impossible) to get the sheet metal clean enough in those areas.

Follow me on Insta: @brzdiy

Posted 25 March 2018 - 07:21 PM

Follow me on Insta: @brzdiy

Posted 26 March 2018 - 10:33 PM

Posted 27 March 2018 - 09:38 AM

Hey Joel,

Top work as always. I'm curious as to why you've removed the roof skin/panel?

Those spot weld drills are awesome!

Cheers

Bennie

Thanks mate,

2 reasons.

1. I still need to attach all the tubes from the rear suspension tubular cradle up to the top of the main hoop but I can no longer drop the cage down to weld the tops of those joints.

2. I am making a carbon roof for it anyway.

Joel.

Follow me on Insta: @brzdiy

Posted 27 March 2018 - 07:18 PM

Follow me on Insta: @brzdiy

Posted 30 March 2018 - 06:34 PM

Follow me on Insta: @brzdiy

Posted 31 March 2018 - 11:09 AM

Posted 31 March 2018 - 05:47 PM

Follow me on Insta: @brzdiy

Posted 01 April 2018 - 06:48 PM

Follow me on Insta: @brzdiy

Posted 01 April 2018 - 07:36 PM

Posted 01 April 2018 - 08:11 PM

Mate epic work!

I bet you were nervous about lining the mount points up correctly to weld them right the first (and only) time. If you weren't nervous, I was for you! Looks tops as always and the to welding - well, I want a tig welder now!

Keep up the good work. I'd love to have half the skills with bending and welding that you have so I could easily make up some front and rear bar work on my L series - and some bash plates to help protect the driveline

Looking forward to future updates. I wish it was Easter every weekend!!

Cheers

Bennie

Thanks for the kind words mate,

Lots of measuring and double checking then go for it. I think bending and notching tube is the most difficult part. I have not been welding very long but I find it rather enjoyable. It's all practice really, the concept is not that difficult, its the practice that makes you better.

cheers

Joel.

Follow me on Insta: @brzdiy

Posted 02 April 2018 - 06:05 PM

Follow me on Insta: @brzdiy

0 members, 0 guests, 0 anonymous users